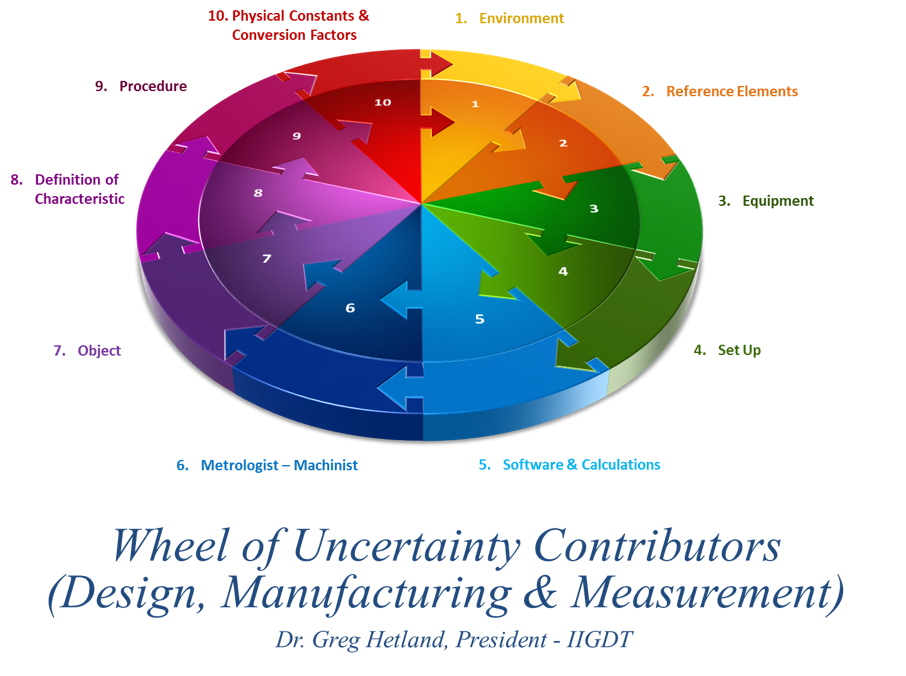

| Definition of Quality to the following disciplines? | |||||||||||||||||||||||||||||||||||

|

Design: Quality of all the specification requirements to confidently and optimally represent the designer’s true functional intent.

Manufacturing: Quality of the manufactured product to confidently ensure optimally conforming product to all the specification requirements.

Quality: Quality of the inspection data to confidently ensure product conformance to all the specification requirements.

|

|||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||

| GD&T Chart per ASME Y14.5M-2009 | |||||||||||||||||||||||||||||||||||

IIGDT has released a new GD&T Symbol Chart supporting the ASME Y14.5-2009 standard. Since the original chart was issued based on the 1994 standard several changes have been implemented. In addition, the IIGDT chart provides clear and descriptive explanations for all symbols. New for this year is the expanded use of 3D profile shown being applied to CAD models to demonstrate the effective use and interpretation of Profile call-outs. Developed by Dr. Greg Hetland, this guide has been widely used in industry and can be found in many companies across the world. Size: 24" (610 mm) x 36" (914 mm) A Poster Paints a Thousand Words... Read about the History of the Chart here. |

|||||||||||||||||||||||||||||||||||

| Dr. Greg Hetland Phone: (612) 670-9311 |

|

IIGDT 12159 Quail Avenue Ln N |