GD&T Seminar Series

|

April 22-26, Salt Lake City, Utah

May 3-7,

Minneapolis, Minnesota |

|

| GD&T Seminars |

|

|

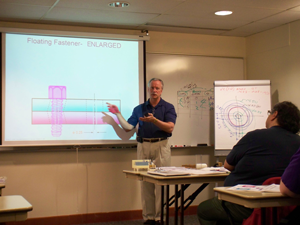

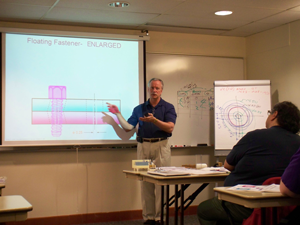

IIGDT has developed a multi-step Geometric

Dimensioning and Tolerancing Seminar Series built upon

years of proven experience in training new users in the

fundamental to advanced topics of GD&T. Whether you are

new, or an experienced user of GD&T, there is a Seminar

level designed for you.

|

|

Click here to visit the GD&T Seminar home page |

|

Precision GD&T and Requirements for

Software Validation |

|

The precision language of Dimensioning & Tolerancing is explicitly defined in the ASME Y14.5M-1994 Standard on Dimensioning and Tolerancing, and is mathematically complimented by the ASME Y14.5.1M-1994 Standard on Mathematical Definition of Dimensioning and Tolerancing Principles. Both of these Standards form the basis for a precise definition of complex surface geometries and should be the basis for mathematical analysis using validated software intended to be in compliance with “FDA 21 CFR PART 11.” |

|

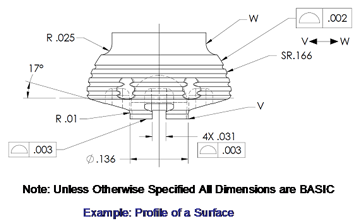

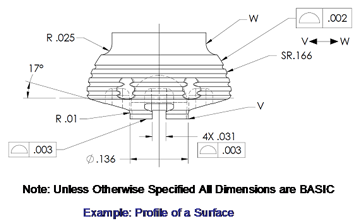

3D Engineering Drawing Example

utilizing Profile of a Surface |

|

|

|

|

|

| Case study for the application of Profile |

|

The availability of advanced CAD design tools and

manufacturing capabilities often incorporate complex,

blended shapes. These surfaces are not easily defined by

the prismatic shapes that we have grown accustomed too

and requires an offset profile band, or halo surrounding

the CAD model.

Test Criteria for

Compliance to Engineering Requirements

Stated Compliance to the engineering requirements as

defined per the ASME Y14.5 and Y14.5.1 Standards and

therefore FDA 21 CFR PART 11 require compliance with the

following “Test Criteria.”

-

Size, which is

defined as having two parts based on “Limits of Size”

criteria defined in section 2.3 of the Y14.5.1 Standard.

This requires compliance to both the “Actual Local Size”

and “Actual Mating Size.”

- Datums which are

based on criteria defined in section 4.3 of the Y14.5.1

Standard which requires:

- Datum “Features of

Size at RFS” (Regardless of Feature Size) to be

simulated as “Actual Mating Envelopes.”

- Datum

“Features of Size at MMC (Maximum Material Condition) or

LMC (Least Material Condition)” to be simulated as

“Virtual Conditions.”

-

“Multiple Features of Size”

defined as a “Single Datum” to be “Simulated as

Patterns” based on “Actual Mating Envelopes” (RFS) or

“Virtual Conditions” (MMC or LMC).

- Position

Tolerances which are based on criteria defined in

section 5 of the Y14.5.1 Standard which requires:

- Analysis of axes based on “Actual Mating Envelope”

principle.

- Analysis of “Bonus Tolerance” based on

applicable features defined at MMC or LMC.

- Analysis of “Simultaneous Requirement” which requires

all features to simultaneously be within their

respective tolerances when the feature control frames

have the same datum, in the same sequence with the same

datum feature modifiers.

-

Analysis of

Single-Segment -vs- Composite Feature Control Frames.

- Profile Tolerances which are based on criteria

defined in section 6.5 of the Y14.5.1 Standard which

requires:

- Minimum Zone fitting algorithms are

used.

- Profile results must always look for the

smallest possible deviation of the actual geometry

(worst case measured point) from nominal geometry,

ideally a CAD model that can be compared to the profile

tolerancing in the feature control frame.

-

Must

ensure “Simultaneous Requirements” are being met which

requires all features to simultaneously be within their

respective tolerances when the feature control frames

(Single-Segment) “have the same datum, in the same

sequence with the same datum feature modifiers.”

- Revision changes of software must be validated to

original “Test Criteria” for continued “Proof of

Compliance” to ensure ongoing integrity of measured

results and conformance to requirements.

|

|

|

| IIGDT Seminars |

IIGDT offers 6 levels of training courses to suite your

business requirements. These are:

|

|

|

|

| |

| Announcements: |

To see our complete schedule please visit the Seminar page,

click here:

|

|

| |

| |

| |

| |

|

Dr. Hetland discusses the critical challenges facing today’s medical OEMs and suppliers

in validating analytical software used for determining

compliance to mechanical drawings for components and

assemblies. This article will make visible some of the risks

and limitations in current software validation and provide

direction to simplify future validation initiatives. click here. |

|

| BONEZONE

Archives |

| |

|